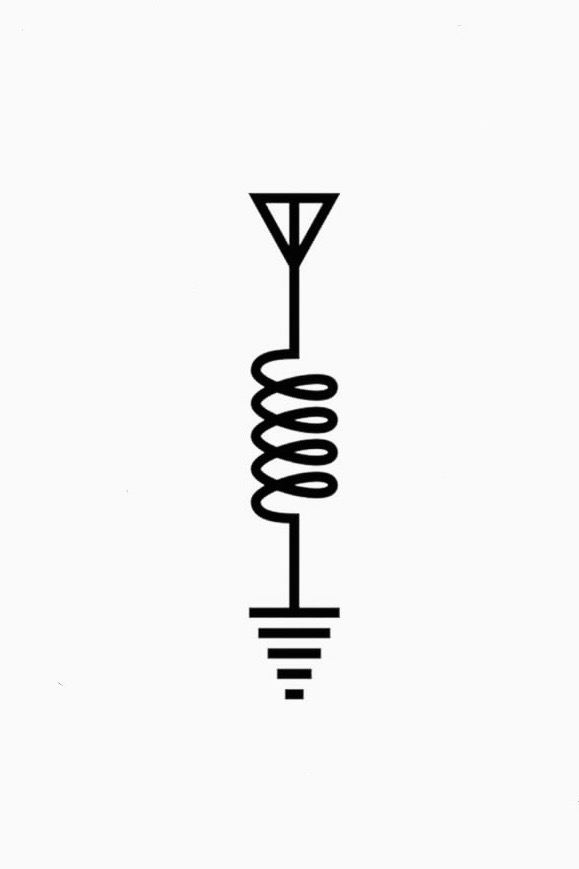

Why is the spring strengthened in the middle?

It doesn’t seem to affect the spring’s buckling characteristics.

My speculation is that it’s to reduce spring noise. That strengthened region at the middle is where the spring will buckle outwards most, resting against the barely visible side rails on the inside of the case. Instead of just one wobbly contact point it now has three rigid ones as a “skate” to reduce the stick-slip noise when opening and retracting the tip. Is this right?

(The pen is a Mitsubishi Uni-Ball Power Tank, pretty much my favorite model.)

I think as a pen manufacturer you just buy bulk springs and then pull them to the desired length. In this case it’s either cheaper for them or they have an excess of longer springs.

You would think that but almost nothing is sourced that way. Easier and cheaper just to have them made to your engineering specs. For my business we make all the hardware in house so we get better part quality than to use off the shelf screws/bolts.

You have your own thread rolling tools!? This is crazy, I’ve never heard of a company making their own hardware where COTS is available.

I work in consumer goods. Not all do it in house but many will. Even if they outsource it the supplier will still make them on demand. It’s just too many parts to keep organized, much easier to get what you need made and deliver it with the other parts during assembly. My company manufacturers around 1mil products a year, individual parts adds up to 10s of millions. We are just a small-mid size producer too

I guess unit cost is going to be pretty levelled at those quantities…

I’ve only really worked with smaller batches so it’s just a bit of a shocking concept.

The spring on its own:

Shenanigans. There’s no way people’s fingernails are that nicely trimmed. I call AI

Only 2 fingers when there should be 5? SHENaNiGANS!

Could be that the machine they have to make springs is designed to make single length springs and they changed it up a bit to accommodate making a double-length version by only changing the cut frequency or something similar

This seems most plausible to me

This prevents spring distortion by effectively creating two shorter spring segments, probably because the pen designer wanted a longer barrel and the mechanical engineer was told to “figure it out that’s why we pay you” and the truth is I have no idea it just sounds plausible enough.

My guess too. A longer spring would have more deflection in the middle. This design could reduce that and increase the spring force.

how would it deflect when confined in a plastic cylinder?

It wouldn’t much, the spring wouldn’t be the exact diameter of the chamber. I could see a Japanese or German pen company over-engineering the spring this way because the cad stress analyzer shows a weakness there

no, you can clearly see from the image posted the spring is snug against the interior wall of the cylinder it’s enclosed in.

Your confusing an external rib for the internal wall. I can see at least a .5mm gap

Mine doesn’t. Seems like an aesthetic feature, since the pen is transparent.

I just checked a couple of my clicky pens and springs are normal

It maintains better tension and will last longer. Great design honestly.

If you can find another pen of the same type, you could see whether it’s consistent. My guess is that the spring “stuck” in that spot when they pulled/set it.

If not, it could be a noise thing.

I just have to say this is a cool photo.

This is one of my favorite models also. It will write well on thermal paper. I especially like how it’ll write on wet paper, which is a big bonus if you do a lot of plumbing

Hell you might wanna look into rite in the rain being a plumber lol!

This was a way more interesting post and responses than I expected.

The way the spring is designed is very akin to taking two separate springs, and attaching them in series. On a highly technical level, this creates a quite different response to motion than a single spring would have. On a lower tech level, it’s approximately the same as regular spring with a different stiffness value.

I’d like to think that some engineers went down the rabbit hole, doing differential equations or modal analysis to solve some complex design problem. More likely it was just a cheap or easy way to solve a manufacturing or supply problem.

Edit: Upon further reflection, spring stiffness does not care about length. The primary concerns are thumb travel (deflection) and force to click (deflection times stiffness). I suspect that deflection is pretty well set by ergonomic factors. This design would reduce the effective spring stiffness by half (and therefore the force). The most obvious other way to reduce stiffness would be reducing wire thickness, which could reduce reliability.

Noise, on the other hand, is an expected result of clicky-pens. People don’t like products behaving unexpectedly. If the design made the pen quieter, you can bet they would advertise it on the packaging.

I kind of hate how much thought I’ve put into this.

I kind of love how much thought you’ve put into this.

I find this stuff fascinating, thank you for typing it out.

First thought: Maybe it helps reduce buckling

But as others said it may behave as two springs in series, giving a different effective stiffness in the equation below

If the coils are the same wire gauge and pitch then putting two springs in series is the same as having one spring of twice the free length.

As stated in other comments it could be:

- to act as a guide for buckling (what you said)

- Aesthetics

Ones i haven’t seen here which I’ll posit:

- to reduce wear on the plastic guides

- to limit travel (the spring could act as the button stop)